Sj75/90/75

Package Size 250.00cm * 220.00cm * 235.00cm Package Gross Weight 29000.000kg SJ75/90/75-2500 ABC Three Layer Co-Extrusio

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | SJ75/90/75-2500 |

| Raw Material | PE |

| Maximum Folding Width of Film | 2500mm |

| Screw Diameter | 75mm*2, 90mm*1 |

| Automation | Automatic |

| Computerized | Computerized |

| Machine Weight | 29t |

| Certification | CE, ISO9001:2008 |

| Die Head Size | 600mm |

| Power | 380V 50Hz 3p 400kw |

| Main Motor Power | 55kw*2, 90kw*1 |

| Size | 8*6*12.5m |

| Rewinder Width | 2800mm |

| Weight | 9500kg |

| Screw Ratio | 32:1 |

| Output | 300kg/H |

| Screw Speed | 15-100r/Min |

| Single Side Film Thickness | 0.03-0.12mm |

| Film Width | 2500mm |

| Transport Package | Warp Film Packing |

| Specification | 12600*9500*13500MM |

| Trademark | HuaRui |

| Origin | China |

| HS Code | 8477309000 |

| Production Capacity | 300kg/H |

Packaging & Delivery

Package Size 250.00cm * 220.00cm * 235.00cm Package Gross Weight 29000.000kgProduct Description

SJ75/90/75-2500 ABC Three Layer Co-Extrusion IBC Internal Cooling Up Rotary PE LDPE LLDPE Blown Film Blowing Extruder Making Machine for Plastic Packaging Bag

Usage:

This film blowing machine is applicable for the materials such as LDPE, LLDPE, HDPE, MLLDPE, etc. It is widely used to manufacture composite film basic material, liquid film, contractive film, protective film, cable film, macromolecule adhesive film, multifunctional industrial film products.

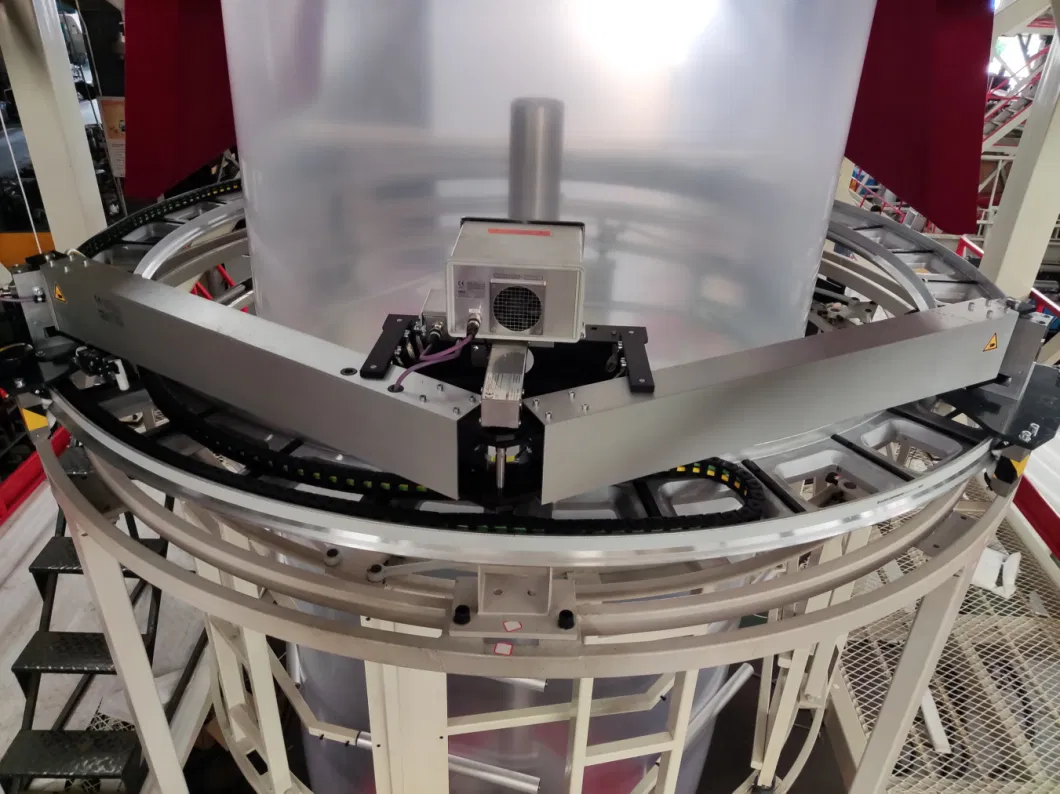

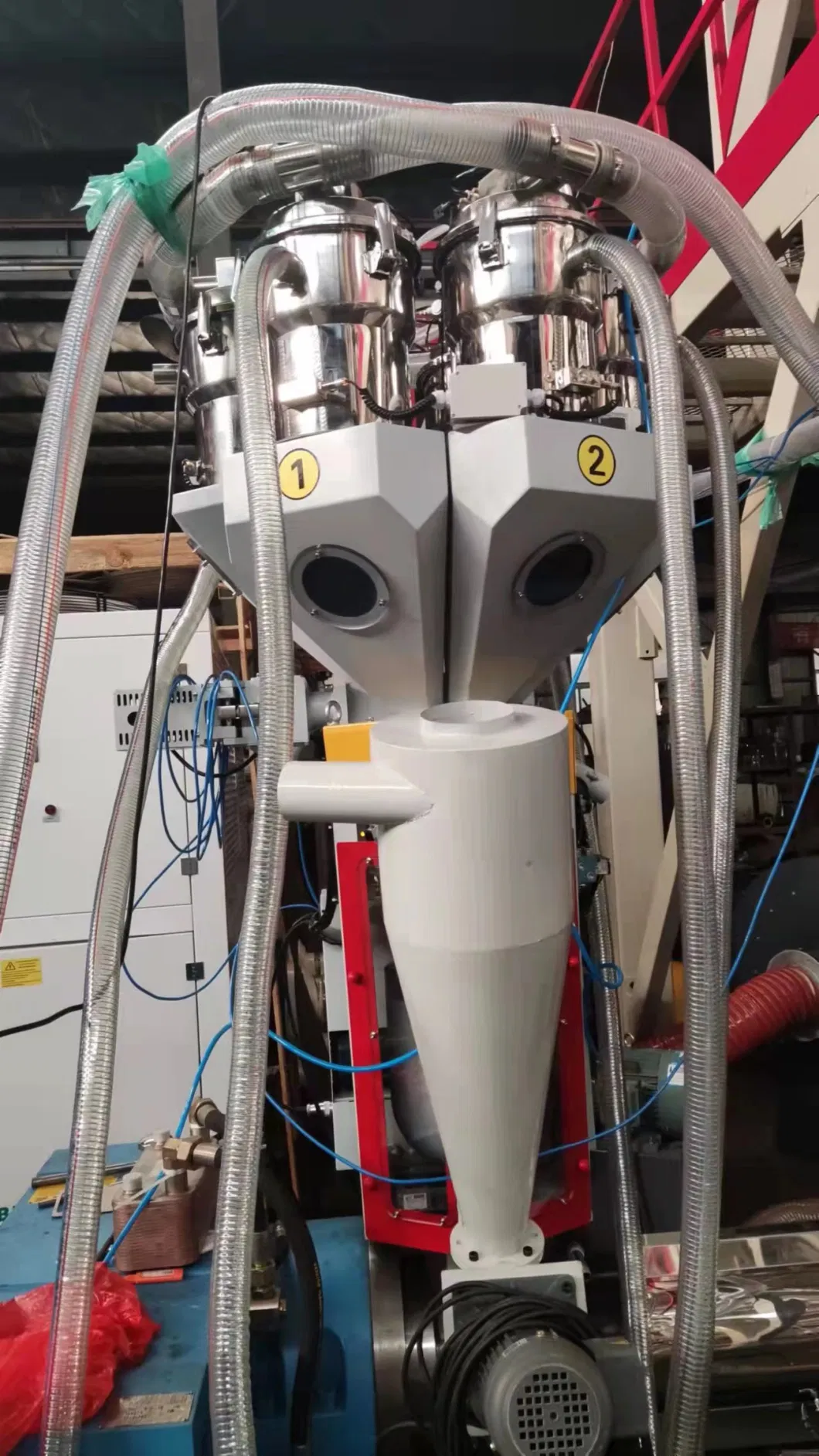

Equipment and technical composition: This machine set is composed of three single screw extruders ,and use of three-layer co-extrusion internal cooling composite die, melt pressure sensing and other high-tech. Plastic extruder (3 sets total)1.1. Screw diameter φ75mm; screw L/D: 32:1; (2 sets) Screw diameter φ90mm; screw L/D: 32:1; (1 set)1.2. Main motor of extruder: power 55kw×2 sets, 90kw×1 set, frequency conversion speed regulation (Inovance inverter);1.3. Screw speed: 15~100r/min1.4. Barrel: Material: 38CrMoAlA nitriding treatment(3 sets)1.5. Die diameter: φ600mm, gap: 2.3, working surface roughness of die head 0.4;1.6. IBC Bubble Internal Cooling System, 10.4-inch screen;1.7. Up traction rotary 1.8 online thickness detection control system1.9. automatic air ring2.0. Maximum rewind width: 2500mm, Max roll width: 2600mmOptional : 1. Equipped with edge material online recycling machine2. Equipped with auto Diffini weighing and loss-in-weight integrated feeding unit3. A set of 25 hp air coolers4. Equipped with two sets of three-phase CW-3006 type sealed discharge rack corona treaters and one set of discharge racks5. Equipped with a set of Edge inserting system, Edge inserting depth is 630mm;

6: Equipped with Switzerland KUNDING online thickness detection control system + automatic air ring:

If you want to know more, can contact us for the detailed Configuring list

More Machine photos:

Our Certication:

Machine Packing and Delivery: